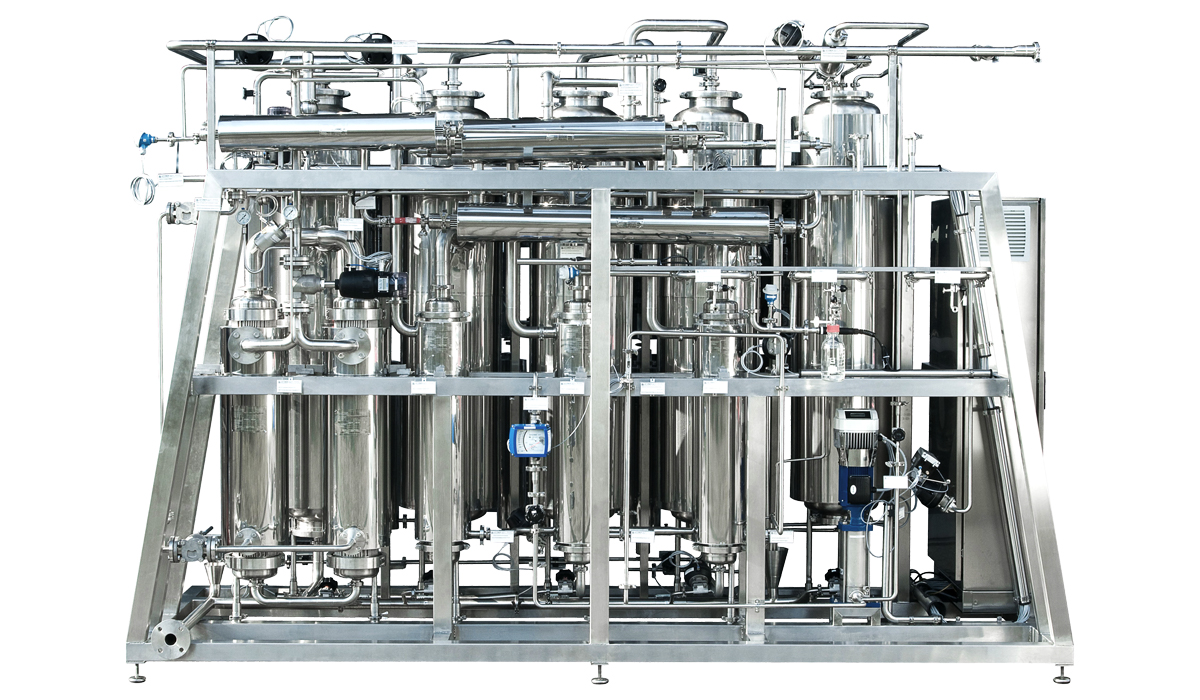

ENERGY EFFICIENT, DURABLE,

ECONOMICAL

Our distillation systems generate WFI by evaporation columns using a natural circulation process. The water is initially evaporated in several evaporation columns and then rises slowly, ensuring that the droplets are efficiently separated. WFI is created when pure steam condenses. Alongside the use for WFI production, some of the residual steam produced can be taken from the first column and fed directly into the pure steam network (twin system for WFI and PS).

EASY MAINTENANCE AND SERVICE

All heat exchangers are outside the pressure columns and are designed as DTS or simple shell-and-tube heat exchangers– our principle for simple and reliable service and maintenance operations. The production capacity and energy efficiency can be optimised with up to eight steam columns connected in series.

THERMAL DEGASSING – ANTI-ROUGING CONCEPT

To comply with EN 285, CO2 and other non-condensable gasses are removed by thermal degassing. The effect of rouging is significantly reduced as a positive side effect of the CO2 degassing.

EFFICIENT STAND-BY OPERATION WITH FULL MICROBIOLOGICAL SAFETY

A drop in temperature in the pressure columns to 80–90 °C in stand-by phases ensures that they are soon operational again while microbiological safety is preserved. This has energy advantages when operating distillation facilities while minimizing possible thermal stress during heating, cooling, and production.

Put your trust in distillation units from EnviroFALK PharmaWaterSystems– their well-designed energy-saving systems meet even the most exacting demands.

Twin systems for WFI and pure steam production

Anti-rouging concept

Blowdown < 1%

Full insulation

Natural circulation process: no burning-in of impurities

Optimised operating and maintenance costs

Ultrapure steam generators